Home > Sustainability > China Plant > Environmental Activities and Results

Environmental Activities and Results

We are working hard to conserve the environment, including reducing greenhouse gas emissions and making effective use of resources, in order to coexist harmoniously with society, our global community and nature ("Living Together").

FY 2022 Targets and Results

| Category | FY 2022 Per Unit Targets | FY 2022 Per Unit Results |

|---|---|---|

| Energy use (drum plant) | Reduce 9% year on year | Increased 4.3 % |

| Energy use (facilities other than the drum plant) |

Reduce 2% year on year | Increased 2.2 % |

| CO2 emissions | Reduce 2% year on year | Increased 2.4 % |

| Industrial waste generation | Reduce 1% year on year | Reduced 7.9 % |

| Water use | Reduce 1% year on year | Increased 18.7 % |

| Implement measures to reduce plastic usage | Implement 3 measures to reduce plastic usage |

|

Energy Conservation Efforts

Since the air conditioning systems are the biggest users of electricity in the plant, we switched to high-efficiency models and assigned managers of each unit to thoroughly manage their operation. We also introduced an energy management system to the plant that monitors areas where energy consumption is particularly high, so we can "see" how much energy is consumed on the system's monitor screen. This has enabled us to identify wasted electricity when production lines aren't running and reduce power consumption. This system has been rated A in the third-party evaluation and certification program for energy management systems established by Dongguan City to reduce energy consumption at companies that use more than eight million kwh per year.

management system

management system

Equipment Replaced with Energy Efficient Models in FY 2022

- 33 packaged air-conditioner units

- 4 chiller air conditioning system units

- 52 small air conditioners

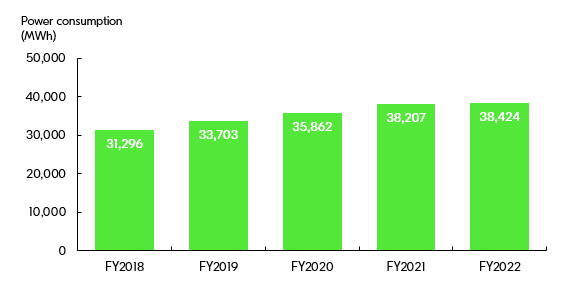

● Historical Power Consumption Data

Efforts to Reduce Industrial Waste

We are actively adopting green purchasing practices to reduce the generation of waste at the source. For example, we switched from disposable cardboard boxes to reusable plastic cartons for parts deliveries. We have also established an online database system that allows each department to post pictures and specifications of work desks, lockers, and other equipment they no longer need to encourage reuse and reduce waste.

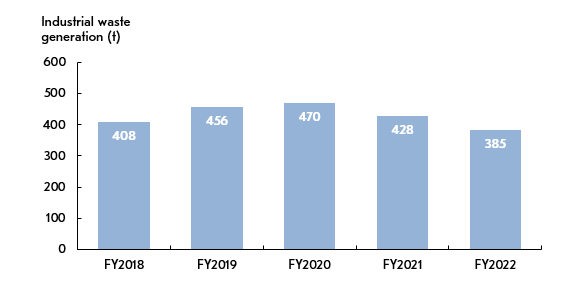

● Historical Industrial Waste Generation Data

Efforts to Reduce Water Use

We are taking various steps to reduce water use, such as switching to water-saving faucets. A gray water treatment system has been installed to reuse the water used for washing parts in the process as cooling water for boilers and chillers in the plant.

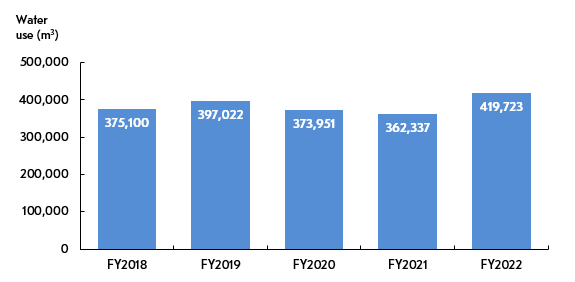

● Historical Water Use Data

Green Production

Implementing Eco Actions

Over the course of four months, from June to September, we have been carrying out various environmental conservation activities under the banner of "Eco Action." With the slogan "Let's all participate in energy-saving and waste reduction, and together build a green production company," we conducted environmental inspections led by the CEO and also engaged in the removal of invasive plants and cleaning activities at nearby parks.

VOC*1 Emission Reduction

We have installed VOC treatment equipment in workshops where organic solvents are used. This has resulted in an annual reduction of approximately 300 [kg] in VOC emissions. Additionally, we have implemented an online monitoring system to continuously monitor factors such as VOC generation concentrations. As a result, in FY 2022, we were able to reduce atmospheric VOC emissions by approximately 90% compared to the previous year. These efforts have led our factory to receive an "A" rank evaluation*2 in the VOC grade assessment system of the Dongguan Ecology and Environment Bureau.

*1 Volatile Organic Compounds

*2 Given to companies that meet conditions such as a VOC removal rate of 90% or higher and an exhaust gas collection velocity of 0.3 [m3/second] or higher, as part of the Dongguan Ecology and Environment Bureau's VOC grade assessment system.

Wastewater Treatment

We have an industrial wastewater treatment facility on the plant's premises and conduct voluntary water quality tests on a weekly basis in addition to third party tests performed every three months.

Green Production Certification

We are working to save energy as well as reduce waste and air pollutants in the production of printers, MFPs, and photoreceptor drums. In August 2020, we were awarded the City Class Green Production certification by the Dongguan Environmental Protection Bureau for our environmental efforts.

See below for the plant's other FY 2022 environmental data.

FY 2023 Targets

| Category | FY 2023 Targets |

|---|---|

| Greenhouse gas emissions | 10% reduction year on year |

| Industrial waste generation | 1% reduction per unit year on year |

| Water use(process water) | 1% reduction per unit year on year |

Implement measures to reduce plastic usage |

|

Home > Sustainability > China Plant > Environmental Activities and Results