Home > Sustainability > Tamaki Plant (Mie, Japan) > Together with Employees

Together with Employees

At the Tamaki Plant our employees are taking initiatives on occupational safety and disaster management to keep their workplace safe and accident-free.

Occupational Safety and Health

morning assembly

(The photo taken before

Covid-19 pandemic)

In order to prevent work-related accidents and help employees stay fit, we remind them about occupational safety and health during a monthly general morning assembly. Employees are briefed on accidents that occurred within the Kyocera Group and are given advice by a public health nurse on how to prevent heatstroke, flu and other infectious diseases, as well as how to interpret their medical test results. We also focus on improving workplace safety and health as well as identifying potential dangers. On top of that, the plant manager and health supervisor along with the head office supervisor conduct safety and health patrols to ensure that there are no dangers lurking in any areas or operations.

Fire and Disaster Management

The town of Tamaki in Mie Prefecture is in an area subject to massive Nankai Trough earthquakes. In order to minimize damage in the event of a disaster, we have installed an earthquake early warning system and conduct a comprehensive fire and disaster drill as well as a nighttime fire and disaster drill every fall. The comprehensive fire and disaster drill includes an initial response drill where participants seek safety with the second the simulated earthquake alert is activated, followed by a simulated call to the emergency phone number (119), an early-stage firefighting drill, and an evacuation drill based on the assumption that a fire has broken out. In addition to all that, the Ise City Fire Department provides instruction on how to operate a fire extinguisher as well as outdoor fire hydrant and conducts a rescue drill from the roof of Plant No. 6 using a ladder truck. The drill also involves a simulated Nankai Trough earthquake using an earthquake simulation vehicle as well as AED and emergency lifesaving training. During the nighttime fire and disaster drill, which is based on a scenario in which a fire occurs in the absence of environmental and safety personnel, security staff take the lead in the training on fire incident reporting, early-stage firefighting, and evacuation.

Traffic Safety

safety campaign

Since many employees use vehicles for commuting and business, we conduct traffic safety workshops and more. We have also established a company car driving license system, allowing only employees who satisfy the in-house certification standards, such as holding a Safe Driver (SD) Card, to drive company cars. Driving analyzers* are installed in company cars to monitor how the cars are used. This information is used to improve safety awareness among employees who drive company cars. In addition, we participate in traffic safety campaigns on the streets during National Traffic Safety Week in cooperation with the local community.

* A driving analyzer records driving data to monitor unsafe driving behavior (such as speeding, hard acceleration, and hard braking).

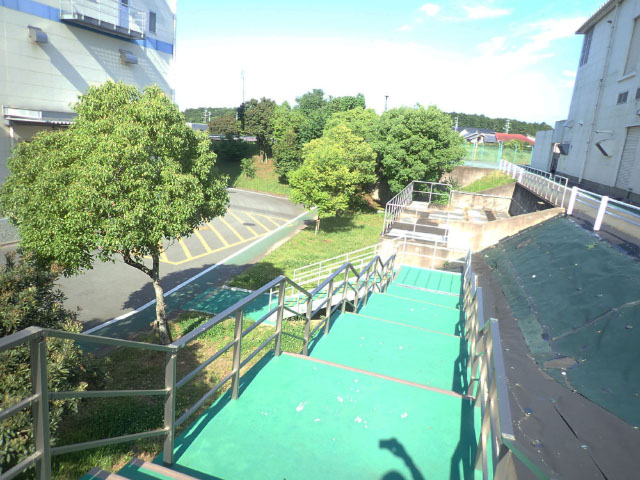

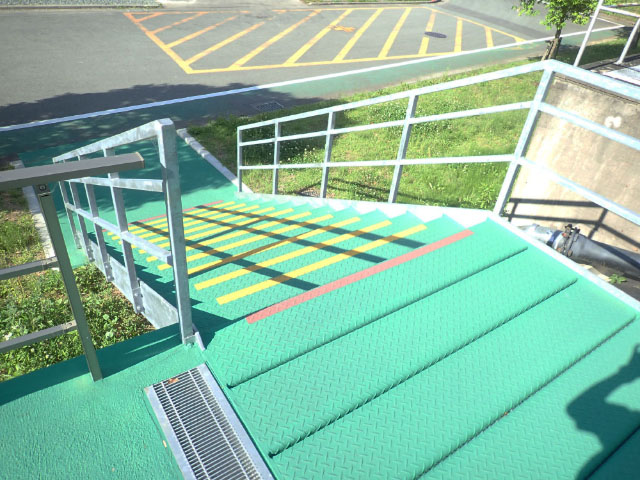

Ensuring Pedestrian Safety throughout the Plant

We have installed green pedestrian pathways throughout the plant. Pedestrian pathways are clearly identified to keep employees and visitors safe while they are walking on the premises.

Employee Welfare

Multi-Purpose Room

We make daily efforts to raise health awareness among employees. As part of these efforts, we maintain a multi-purpose room equipped with exercise and fitness equipment and ping pong tables to provide employees with opportunities to work out and interact with one another. This helps create a thriving work environment while enabling every employee to work on being as healthy as possible.

Home > Sustainability > Tamaki Plant (Mie, Japan) > Together with Employees