Next to Zero Water Use

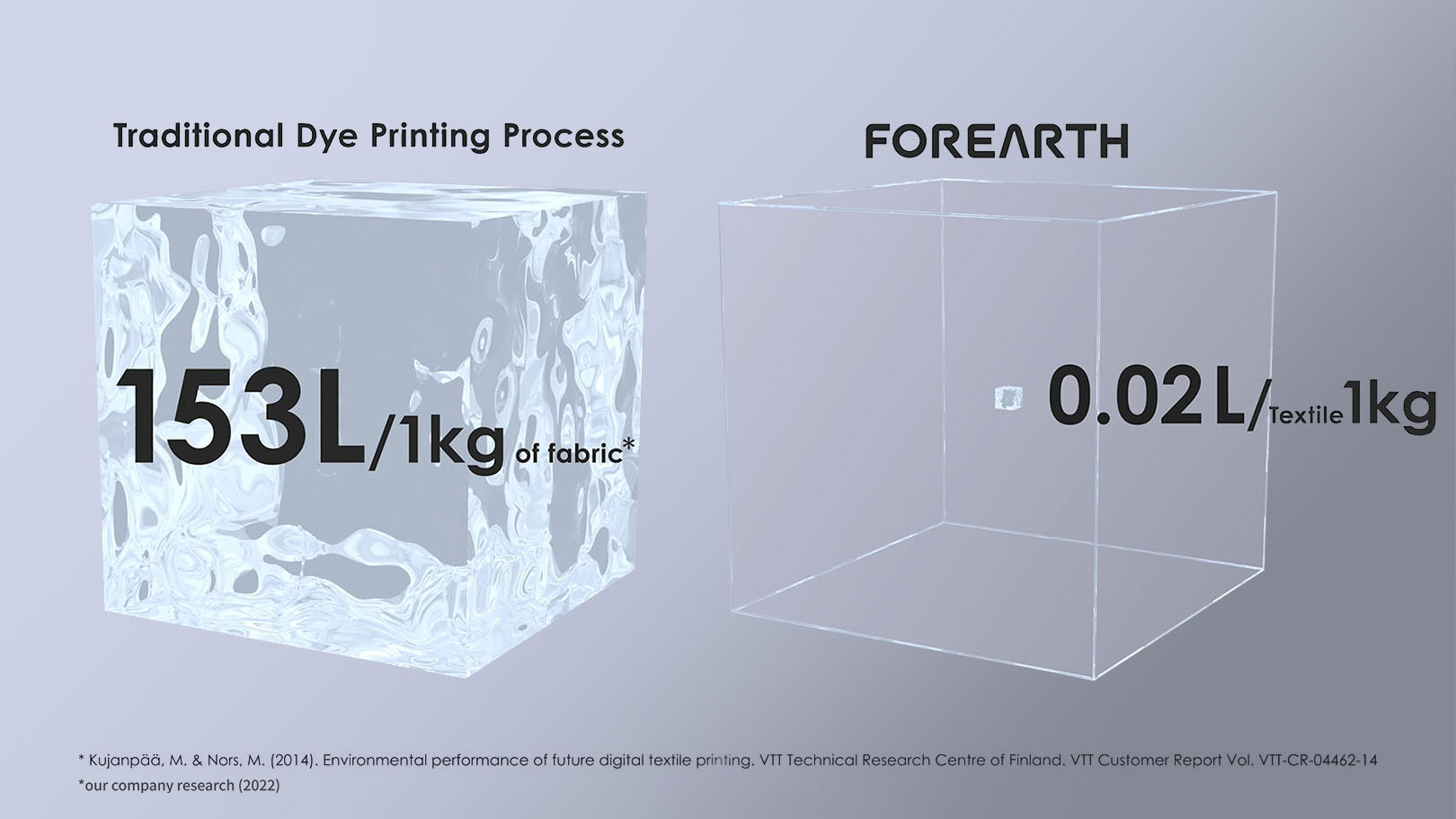

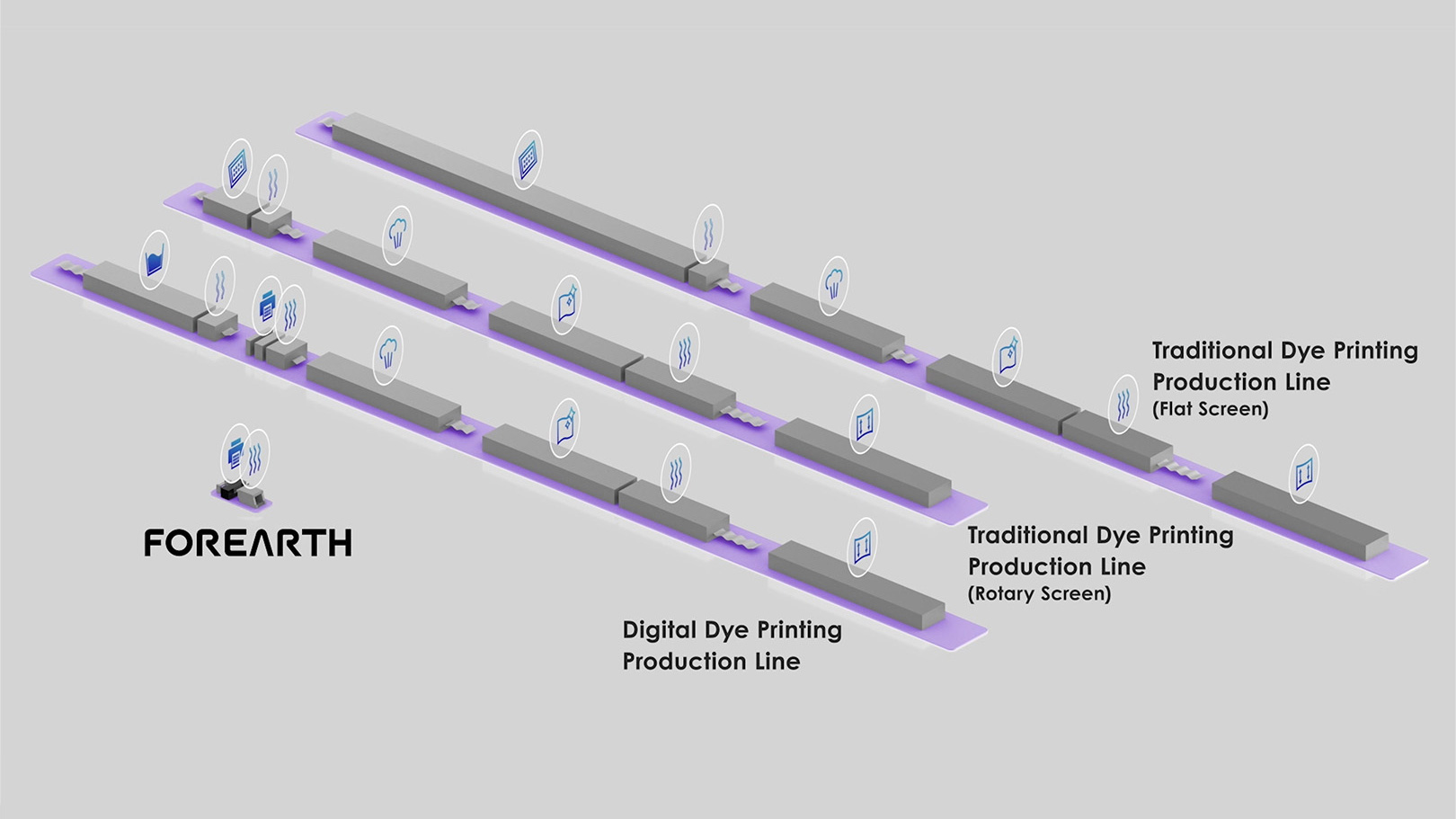

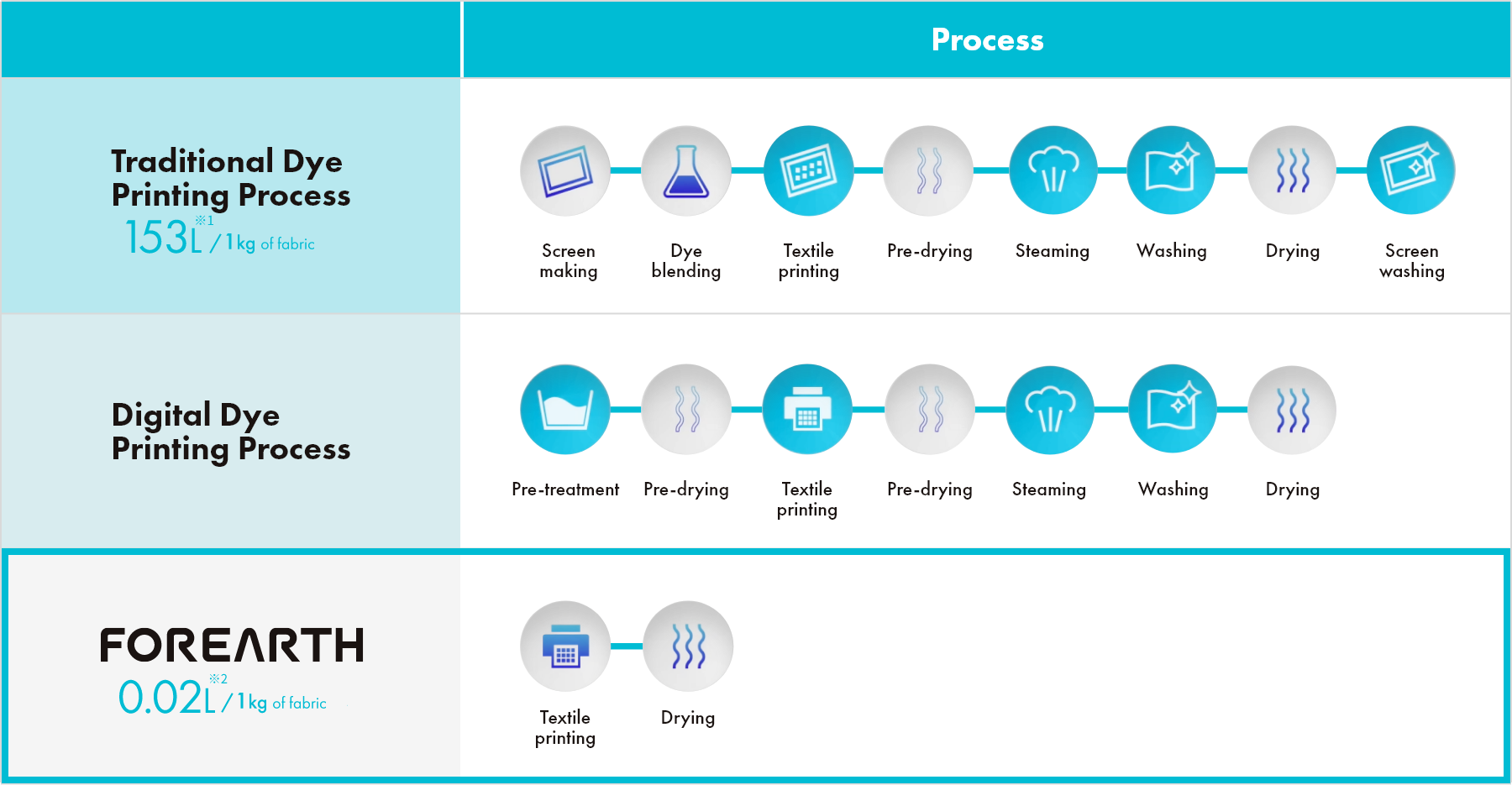

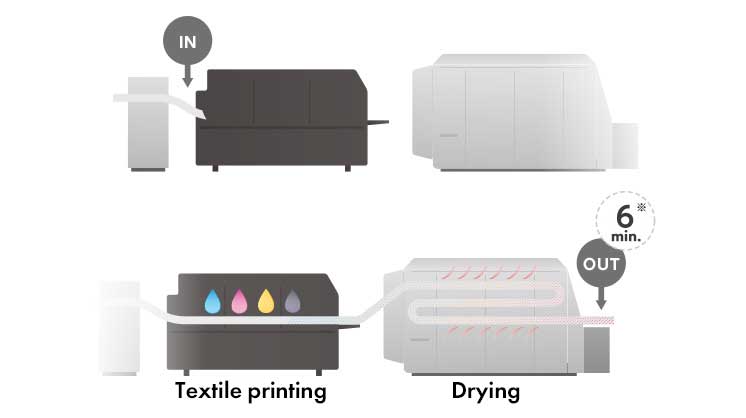

Traditional dye printing, which has four processes requiring water, uses 153L※1 of water per 1kg of fabric while FOREARTH has a simple two-step printing and drying process. No water is used in the printing process based on the concept of "WATER FREE".

Kyocera focuses on reducing water usage not only for the printing process but also for the maintenance process. FOREARTH also recycles cleaning water used for the conveyor belt with filters resulting in water consumption per 1kg of fabric reduced to 0.02L※2. FOREARTH contributes to the realization of sustainable textile printing.

- ※1 Kujanpää , M. & Nors , M. (2014). Environmental performance of future digital textile printing. VTT Technical Research Centre of Finland.VTT Customer Report Vol. VTT CR 04462 14

- ※2 Based on Kyocera research, in 2022

Reducing Environmental Impact to Achieve a Sustainable World.

FOREARTH concept does not require separate facilities for pre- and post-treatment processes needed in conventional textile printing. It contributes to reducing water usage dramatically and also helps to reduce CO2 emissions and energy consumption.

Expand Your Creativity on Diverse Fabrics.

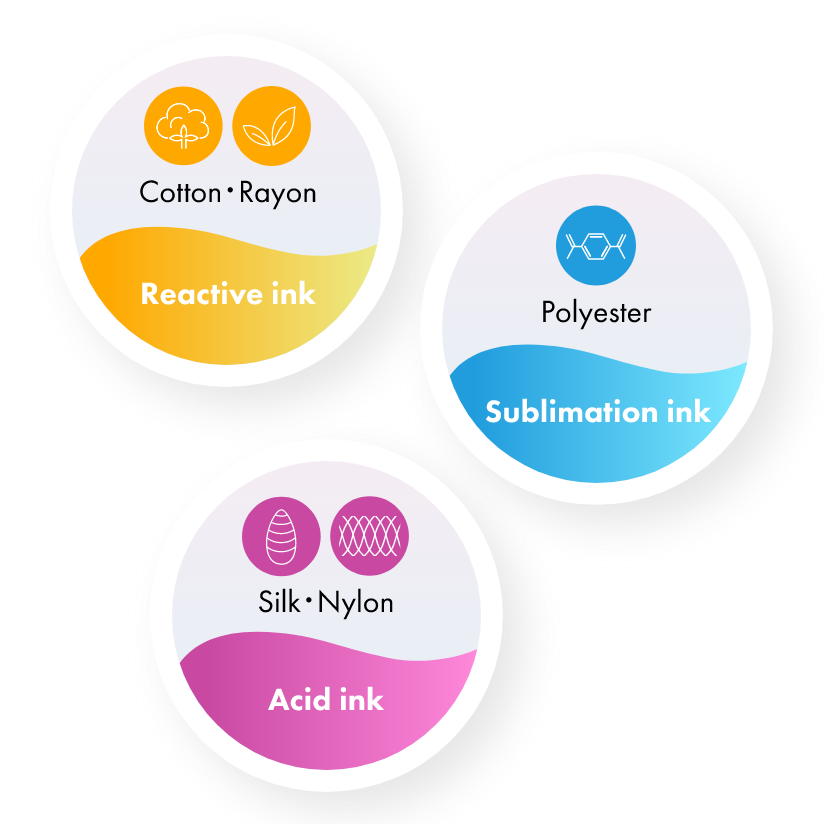

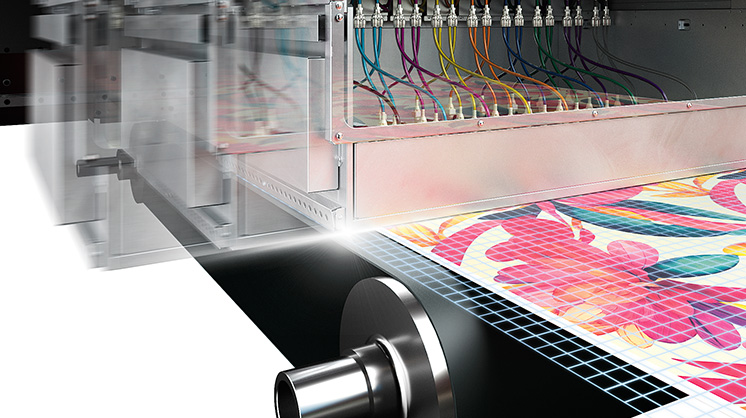

FOREARTH uses Kyocera's proprietary pigment ink, pretreatment liquid and finishing agent to realize high quality printing on a wide range of fabrics, including cotton, silk, polyester, nylon and blended fabrics.

In addition, by discharging the pretreatment liquid, pigment ink, and finishing agent in a continuous cycle, the product maximizes the performance of each element and maintains softness of the fabric.

This digital texile printer is free from the limitation of screen printing. As a result, FOREARTH achieves vibrant and high-definition printing with a flexibility in design size.

It can be used across a broad range of categories- from women's fashion to sports and kids' wear and home textiles. FOREARTH expands creative possibilities and helps create new value in the textile and apparel industry.

FOREARTH Adapts to Various Types of Fabrics Using a Single System.

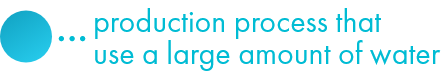

With conventional inkjet printing systems, dye inks need to be selected for types of fabric, and the system needs to be prepared separately for each ink type.

Kyocera's circulating inkjet head and original pigment ink enable printing on a wide range of fabrics.

Get the Design You Want, Now.

FOREARTH’s system has only two steps - printing and drying.

Because it does not require separate facilities for pre- and post-treatment processes needed in conventional textile printing, it enables to drastically shorten the numbers of processes from design to production.

With FOREARTH, it is possible to print only the amount needed and respond to short lead time requests and avoid a surplus in inventory.

Environment-friendly and Efficient for Business

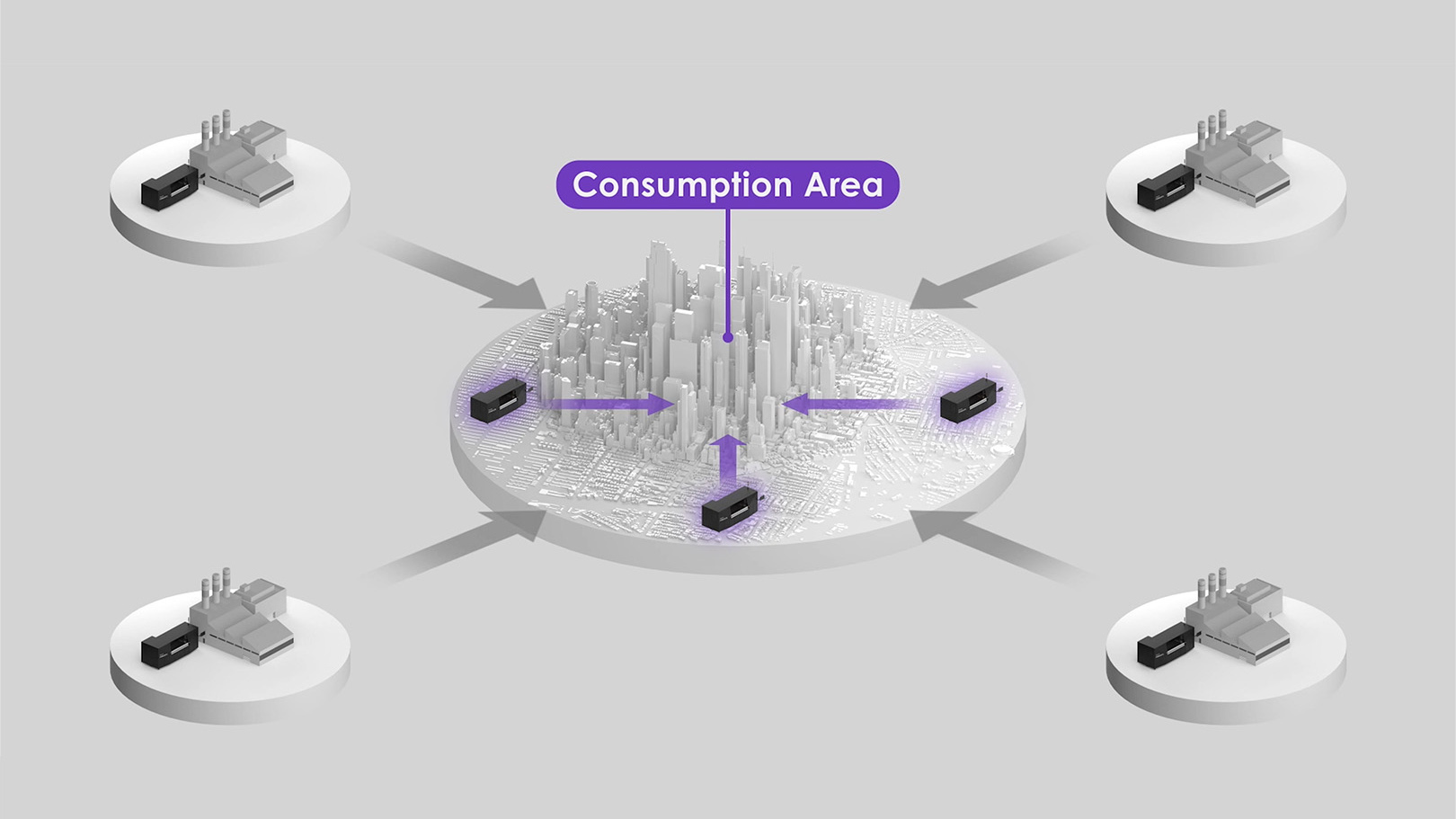

Traditional dyeing factories are operated in areas close to water resources since large amounts of water is used for production.

On the other hand, FOREARTH uses very little water for printing so that production can be set up almost anywhere, including on-shore, near-shore, or more suitable areas close to consumers. FOREARTH contributes to the reduction of lead time and logistics costs.

Our earth-friendly printing solution FOREARTH contributes towards the vivid creation of a more beautiful,

sustainable world by expanding freedom of choice in design, time and location.

Kyocera aims to open up possibilities of textiles though FOREARTH, featuring the concepts of "WATER FREE," "CREATIVE FREE" and "LOCATION FREE."

Kyocera Technologies * Over 100 patent applications worldwide (as of February 2025)

All in One Textile Printing System

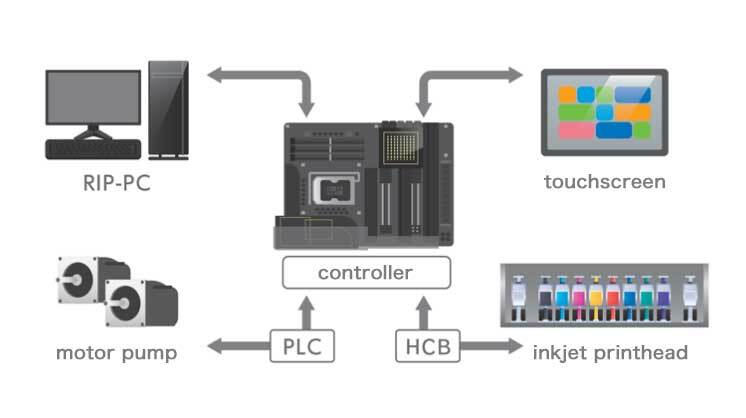

KIPS (Kyocera Integrated Printing System)

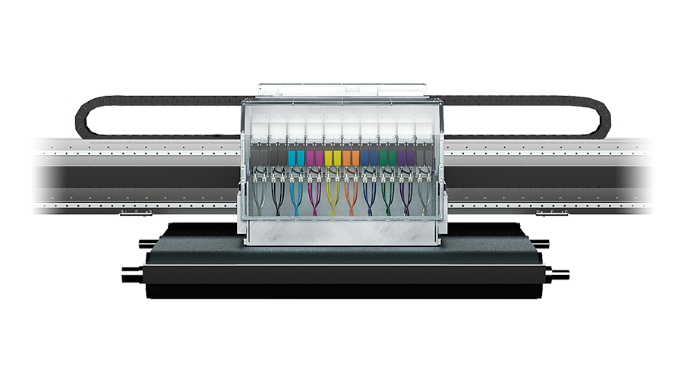

FOREARTH installs Kyocera's inkjet print head which is top global share※ for its digital textile printing, and by incorporating all in one textile printing system, KIPS, proprietary Picfy pigment ink, pre-treatment liquid, and finishing agent, the water free concept is realized.

※In terms of printing area, according to 2022WTiN

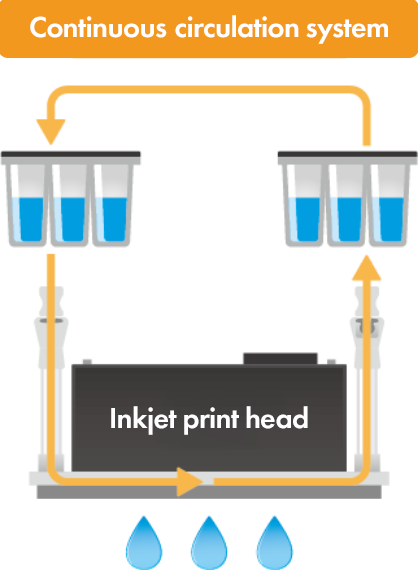

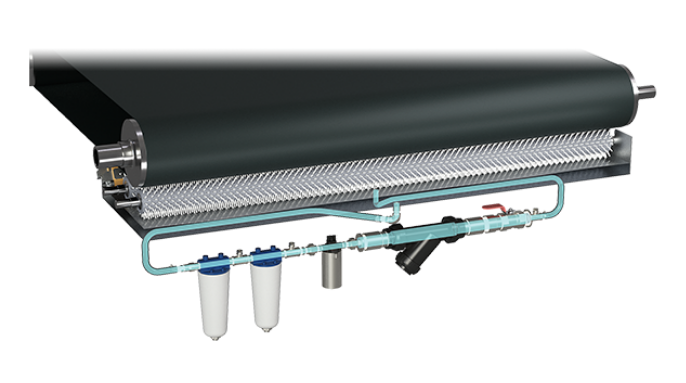

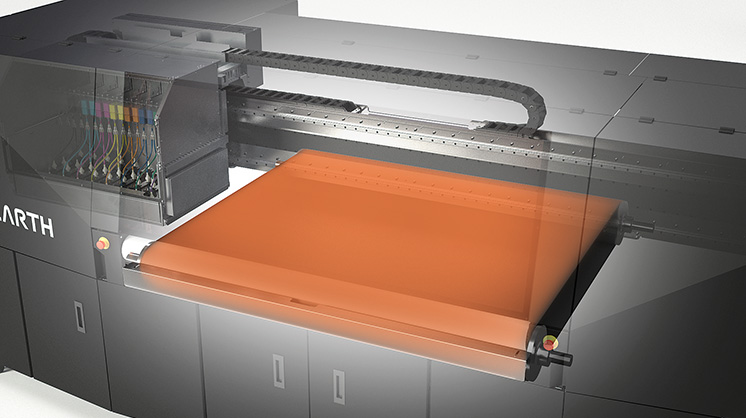

Circulating Belt Cleaning System

Reduces Water Consumption to the Utmost

Kyocera focuses on reducing water usage not only for printing process but also maintenance system, FOREARTH recycles cleaning water used for the conveyor belt with filters.

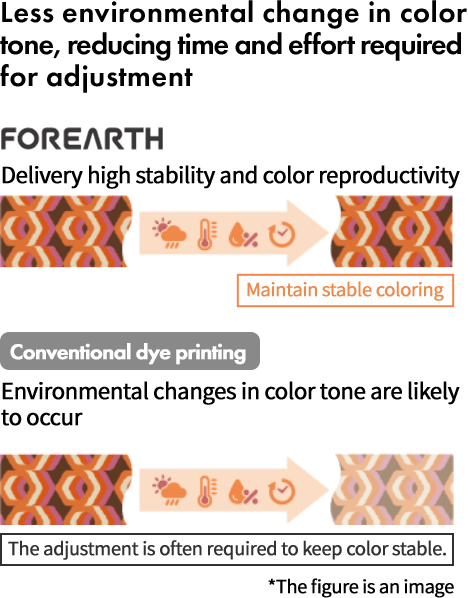

Kyocera's Pigment Ink Picfy, Pretreatment Liquid and Finishing Agent

FOREARTH discharges pretreatment liquid, pigment ink, and finishing agent in a continuous cycle that enables maintaining softness of a fabric.

ECO PASSPORT International Safety Standard Certification

Kyocera's Picfy water-based pigment ink, pretreatment liquid, and finishing agent have all obtained the ECO PASSPORT certification, an international certification system for the safety and environmental impact of textile products. ECO PASSPORT certification shows that textile products meet the inspection standards for hazardous substances contained in them and guarantees that the products are safe and secure.

-

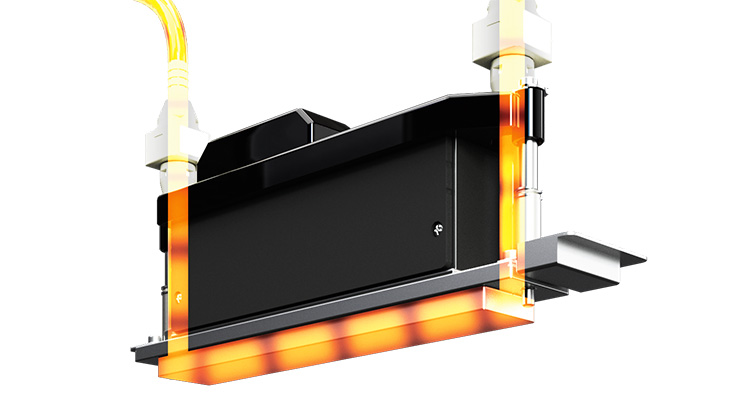

Latest Circulating Printheads for Stable Print Quality. Constant circulation keeps ink temperature and viscosity stable.

-

Automatic Cleaning System to Keep Printheads in Optimum Condition for Stable and High-quality Printing

-

Sample Print Mode which Makes it Possible to Print on Small Fabric Size from A4 (210 x 297mm). It reduces the time and fabrics waste for sample printing.

-

Equipped with Conveyor

Belt Heater -

FOREARTH's Buffer Tank Enables Ink Replacement even during Printing. It reduces down time.

-

Full Frontal Access Design for

Efficient Maintenance -

KIPS(Kyocera Integrated Printing System) Enables Speedy Printing

-

High-precision Linear Carriage Drive. It ensures precise printing quality in short time.

-

High-speed Data Communication System by Integrated Device Control with High-speed 10G Network

Aiming for a Sustainable Future

Kyocera Textile Printing

Textile Printing

Kyocera aims to create a better future for the world, using the power of technology to solve issues we face as a global society.

This ambition is rooted in our Kyocera Management Rationale: to contribute to the advancement of society and humankind.

Kyocera has successfully developed countless products by applying to and developing fine ceramics technology, and it has continued to explore new markets. Today, Kyocera is involved globally in everything from electronic components to finished products, and even infrastructure. In the world of digital textile printing, Kyocera holds the top share※ of inkjet printheads, the key component of digital textile printing.

The FOREARTH sustainable textile printer was created through the combined knowledge and technology of the Kyocera Group, which is expanding into various fields, and creating technological synergies to reduce environmental impacts and contribute to a better future.

FOREARTH embodies Kyocera’s desire to leave a beautiful future to our children. Kyocera is committed to its creative journey, and contributing to humankind and to society.

※ In terms of printing area, according to 2022WTiN

Printhead

Kyocera circulating inkjet printhead

No. of printheads

Max. 18 (Color: 16; Pretreatment Liquid: 1; Finishing Agent: 1)

Ink type

Water-based pigment ink

No. of colors

Up to 8 (CMYK + 4 special colors)

Ink capacity

10 L

Max. print width

1800 mm

Max. cloth widht

1850 mm

Resolution

600×600 dpi

Print speed

Standard: High-quality mode; 2 pass, 250 ㎡/h

Cloth transport

Adhesive belt

Belt cleaning

Automatic water circulation system

Feeder

Roll diameter: up to 300 mm / Roll weight: up to 150 kg

Dimensions

4600×2000×2000 mm

Net weight

3500 kg

※Product specifications are subject to change without notice.

"FOREARTH" and "Picfy" are trademarks or registered trademarks of Kyocera Corporation in Japan and other countries.