TASKalfa Pro 15000c

Featuring reliable and durable print heads, with exclusively developed inks and ink discharge technology. Ensures outstanding print quality and stability.

-

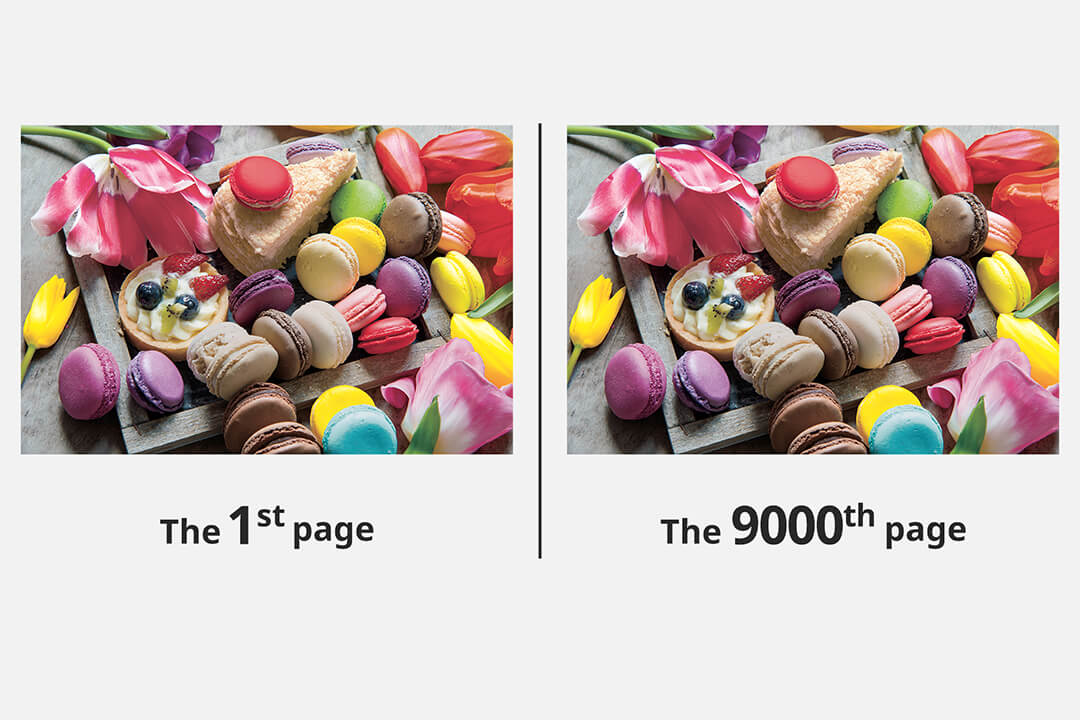

Stable image quality

The TASKalfa Pro 15000c enables continuous printing with consistent color. Unlike electrophotography, calibration (Operation for keeping toner concentration constant in developing process) is not required, and be able to achieve non-stop printing without downtime. In addition, unlike offset printing, there is no need for color adjustment, which requires constant staffing. Hereby achieving high productivity and reduction of manpower at the same time.

-

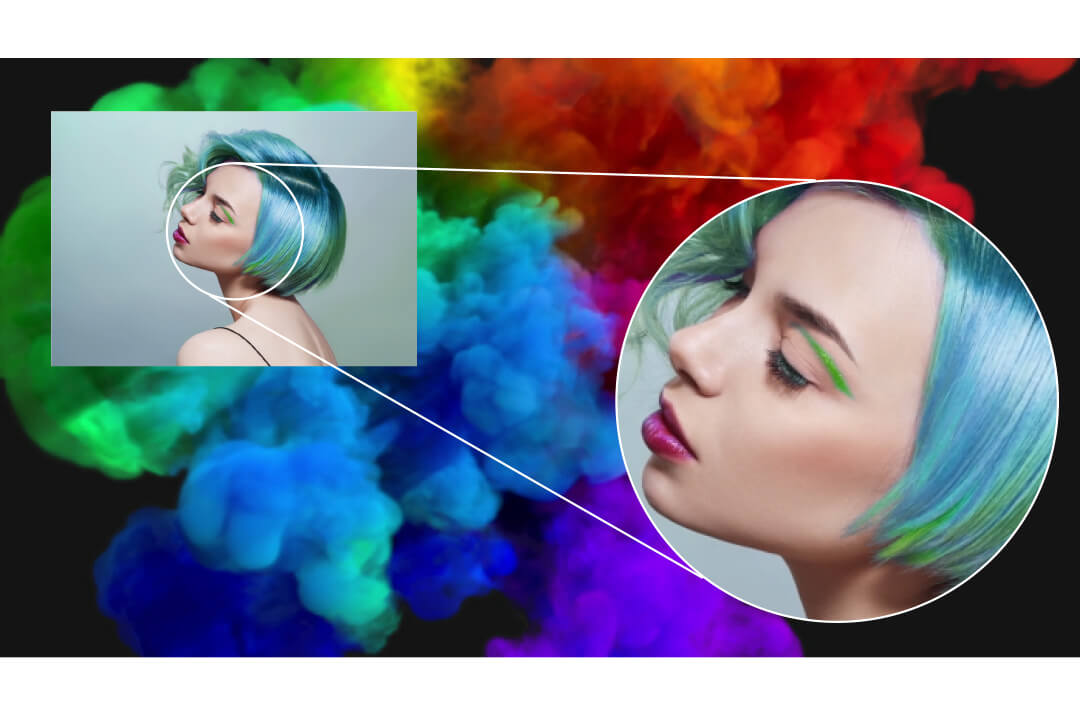

Adjusting nozzle spray timing

The TASKalfa Pro 15000c equips with a speed sensor that detects and share the information of the speed of the passing paper to the control of ink ejection in real time, and adjusts ink discharging position at the optimum timing. Thereby ensures accurate dot position on the paper to achieve outstanding image quality and color consistency without color shift.

-

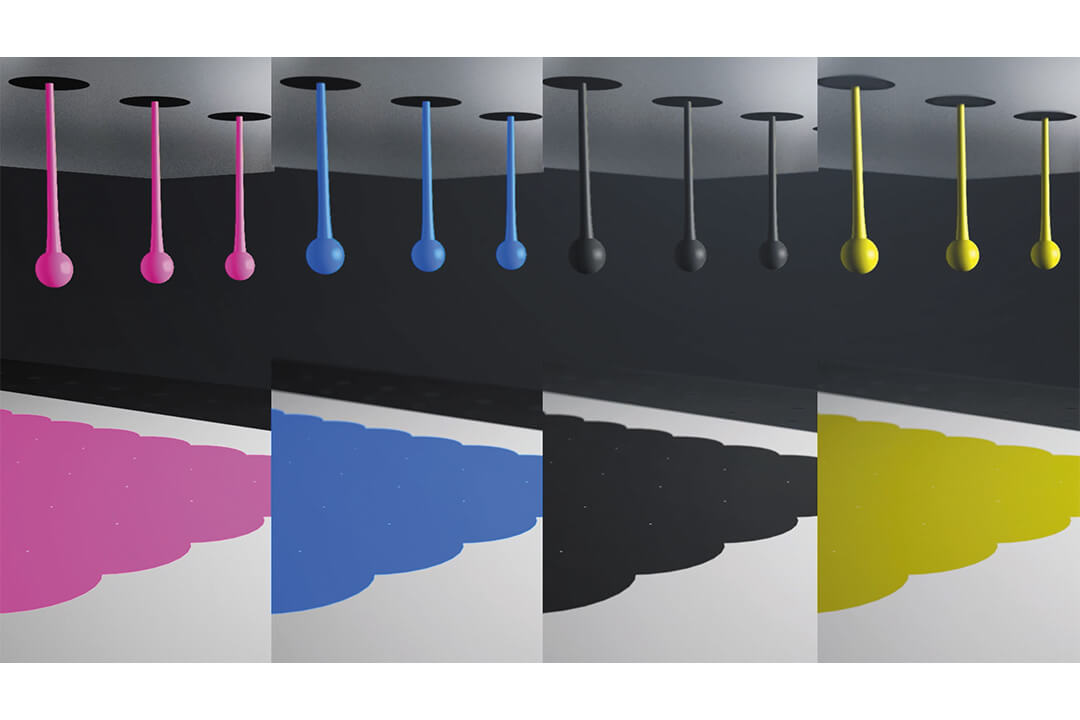

Kyocera developed water-based pigment ink

The TASKalfa Pro 15000c uses water-based pigment ink with superior light fastness and water resistance. The Kyocera developed ink maintains color development while being quick-drying to prevent feathering as well as ink bleeding, enables low-flow dot reproduction even with high-speed printing of 150 sheets per minute. It delivers superior reproduction of sharp text and fine lines, and smooth gradations with little moire (fringe interference) for patterns and photos, suppressing shine with a calm texture that is gentle to the eyes.

-

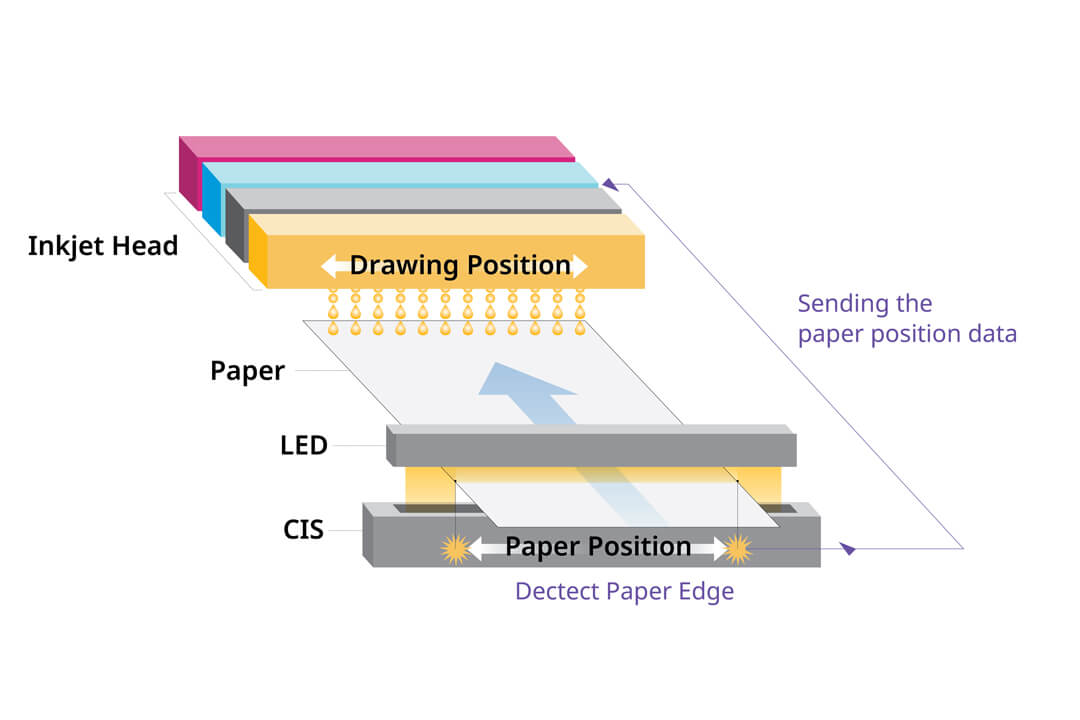

Precise front to back registration

The CIS (contact image sensor) senses paper edges position during printing and sends paper position data to the video controller in real time. Using the paper position data, the position accuracy with respect to the paper is suppressed to ± 0.5 mm or less. Using the paper position data, the position accuracy with respect to the paper is suppressed to ± 0.5 mm or less. Achieving high-precision during double-sided printing without using any moving parts. The CIS also detects areas of media and ensures ink is discharged only on the media, prevents ink from being ejected to areas where paper corners are broken or punched, and prevents image deterioration due to ink adhesion at the transport level.

-

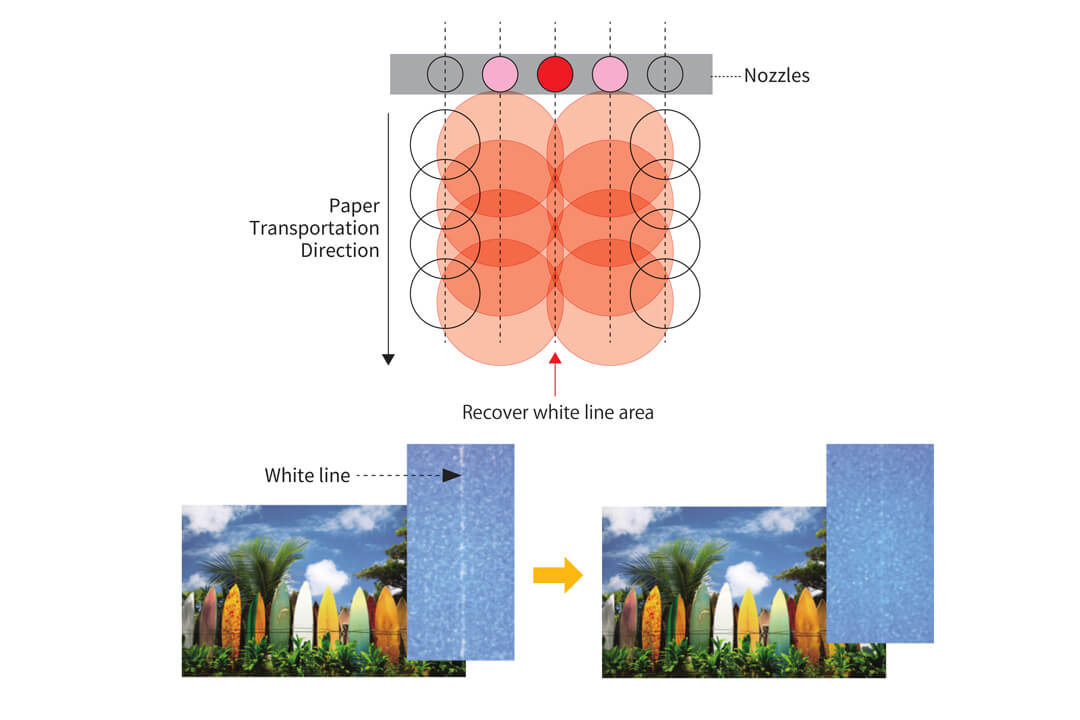

White lines correction

By performing nozzle correction maintenance with a scanner, white lines appeared on paper can be compensated to correct the output image by ejecting ink from nozzles that are close to where the white lines occurred during printing.