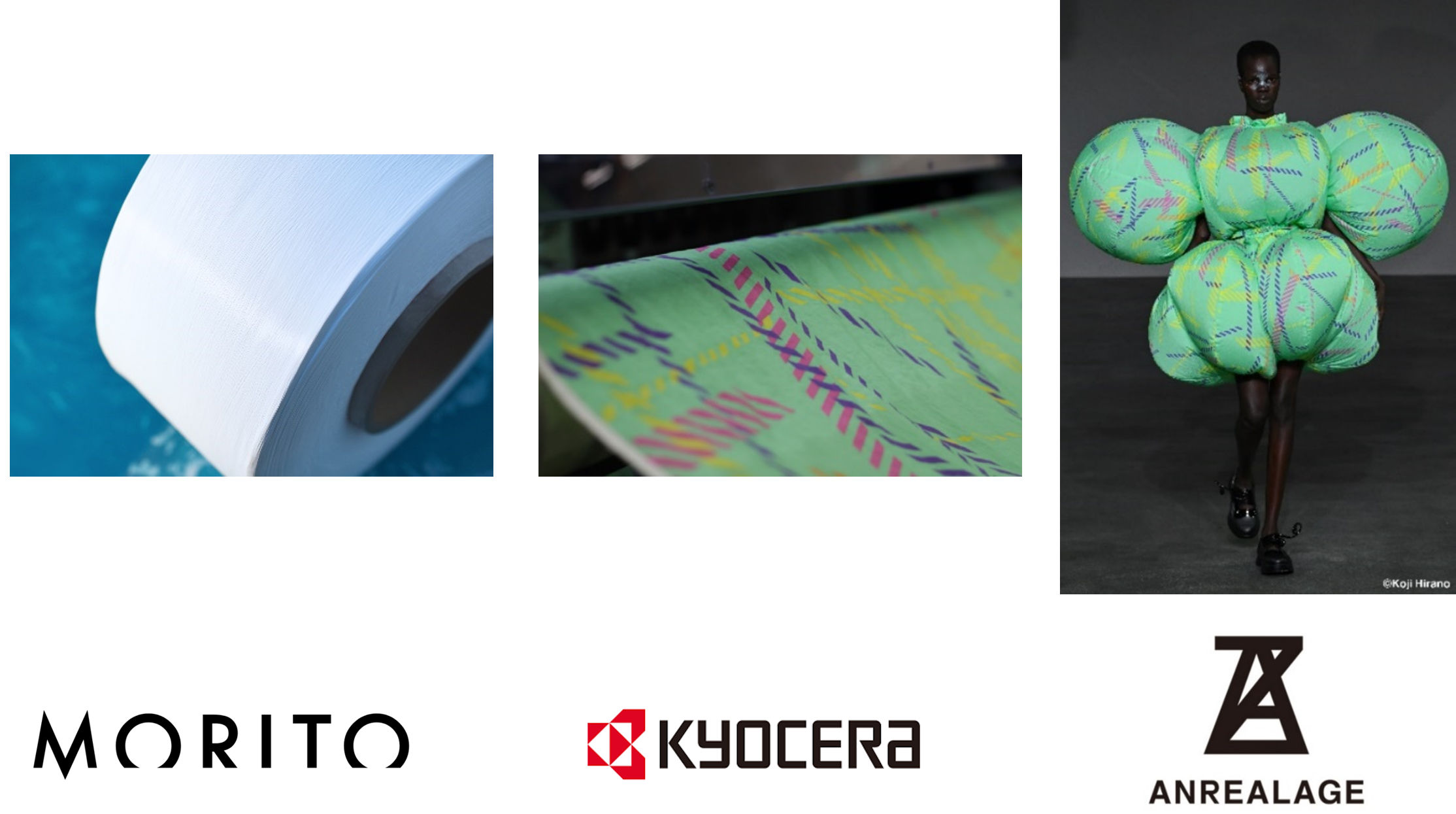

Fashion brand ANREALAGE announced a collaboration item of inkjet textile printer FOREARTH and waste fishing net recycling yarn MURON at Paris Fashion Week®.

Kyocera Document Solutions Inc. (President: Hironori Ando) is pleased to announce that the fashion brand "ANREALAGE" has announced a collaboration item at the women's collection for Spring/Summer 2025 Paris Fashion Week®. The item was created with fabrics composed of "MURON" yarn made from recycled waste fishing nets, then printed on using Kyocera's inkjet textile printer "FOREARTH". MURON was developed by MORITO APPAREL CO., LTD. (President: Hiroyoshi Mori).

This collection presented by "ANREALAGE" was produced with the concept of "visualizing the invisible power of wind". The wind makes waves on the surface of the water, creating currents that promote evaporation and form clouds. This causes rainfall and maintains the Earth's water cycle. Thus, the interaction between Earth's wind and water plays a very important role in the environment.

With this concept in mind, a collaboration between Kyocera’s printing technology of “FOREARTH” , which reduces water use by 99.98%, and “MURON” recycled yarn from used fishing nets, which helps resolve the issue of marine plastic pollution, was created as a special and sustainable fabric that was visualized in the “ANREALAGE” collection.

Recycled fishing net yarn "MURON"

Recycling of waste fishing nets and gear has become an important issue from the viewpoint of marine plastic pollution worldwide. According to a survey of marine litter conducted by the Ministry of the Environment in fiscal year 2016, discarded fishing nets and ropes account for approximately 40% of the total weight of plastic litter that washes up on shore in Japan.

Recycling of waste fishing nets and gear has become an important issue from the viewpoint of marine plastic pollution worldwide. According to a survey of marine litter conducted by the Ministry of the Environment in fiscal year 2016, discarded fishing nets and ropes account for approximately 40% of the total weight of plastic litter that washes up on shore in Japan.

With this in mind, Morito Apparel is focusing on recycling discarded fishing nets. "MURON" is made from 100% recycled waste fishing nets collected in Japan. By adding a chemical recycling process, they have succeeded in developing a high-quality and stable fiber.

Click herefor more information on "MURON"

Comment from "ANREALAGE" designer Mr. Kunihiko Morinaga

We thought that printing "FOREARTH" on waste fishing net fabric would be a sustainable approach to water. We believe that recycling discarded fishing nets into fiber will help protect the global environment and water. I feel an affinity between the social significance of "FOREARTH", which minimizes the use of water, and textiles made from recycled waste fishing nets.

We thought that printing "FOREARTH" on waste fishing net fabric would be a sustainable approach to water. We believe that recycling discarded fishing nets into fiber will help protect the global environment and water. I feel an affinity between the social significance of "FOREARTH", which minimizes the use of water, and textiles made from recycled waste fishing nets.

There were concerns that textiles printed with conventional textile printers would become hard or not have the unique texture of the fabric. However, when I looked at the textile printed with "FOREARTH", it neatly reflected the shading created by the subtle unevenness, and I was very impressed that the material was light, and that waste fishing nets were reborn in this way and existed anew.

As fashion designers, I believe that the collection we present should be based on the future of the Earth and the future of the environment. This includes the use of recycled textiles from discarded fishing nets in a fashion context, as well as the use of "FOREARTH" printing technology. However, if only one brand uses this, it will not lead to a big movement in the future. I hope that not only ANREALAGE but also many brands and people involved in fashion will take notice and adopt it.

Features of the inkjet textile printer "FOREARTH"

1)Water Free ConceptDramatically reduces water usage in textile printing.*

2)Creative Free

Proprietary water-based pigment ink realizes both soft hand-feel prints and high fastness in a wide range of fabrics.

3)Location Free

Textile printing does not rely on water resources, so it supports optimized production volumes and optimized manufacturing location settings as well as contributes to the reduction of logistic costs, time, and excess inventories.

As "FOREARTH" dramatically reduces water usage in textile printing to next to zero, it does not require separate facilities such as for steaming and washing needed in pre- and post-treatment processes of conventional textile printing. This will also contribute to a significant reduction in energy consumption and CO2 emissions. Furthermore, it achieves a soft texture maintaining softness of the fabric that are important in the textile and apparel industries, and enables high-definition printing on a wide range of fabrics such as cotton, silk, polyester, nylon, and blended fabrics.

Our company aim to contribute to solving issues such as water pollution and high CO2 emissions in the textile printing world through our "FOREARTH" sustainable inkjet textile printer. We will continue our creative path to solve various social issues facing the world with the power of technology and create a better future.

- * FOREARTH has a two-step printing and drying process. No water is used in the printing process based on the concept of "WATER FREE". Kyocera focuses on reducing water usage not only for the printing process but also for the maintenance process. FOREARTH also recycles cleaning water used for the conveyor belt with filters resulting in water consumption per 1kg of fabric reduced to 0.02L (Based on Kyocera research, in 2022).

Inquiries

- Customers except within EU

-

KYOCERA Document Solutions Inc., Corporate Communication Section

- Customers within EU

-

KYOCERA Document Solutions Europe Management B.V.

- Kyocera Document Solutions Inc. ensures adherence to local data protection regulations. We have detected that your inquiry comes from within the EU. Therefore, due to the EU's General Data Protection Regulation, please note that your request will be forwarded to our regional headquarter: Kyocera Document Solutions Europe Management B.V.

- *This news release is current, as of the date of publication.