Kyocera's FOREARTH Technology Powers HATRA's 2025 AW Collection at Rakuten Fashion Week TOKYO

Kyocera Document Solutions Inc. (President: Hironori Ando) is pleased to announce that fabric printed by the eco-friendly inkjet textile printer “FOREARTH”, which enables printing on a wide variety of fabrics, was adopted by Mr. Keisuke Nagami, founder and designer of Japanese fashion brand “HATRA”, and was presented at Rakuten Fashion Week TOKYO 2025 AW on March 20th.

The collaboration this time was made possible by Keisuke Nagami, who actively embraces new digital technologies such as 3D cross simulation and generative AI. He recognized the innovative printing technology of FOREARTH, which allows for printing while maintaining the excellent texture of the fabric.

About Keisuke Nagami

Keisuke Nagami studied couture*1 at ESMOD*2 in Paris and founded HATRA in 2010 after graduating from the Paris Master Course program in 2009. "HATRA" is known as a unisex brand that was among the first Tokyo brands to focus on the relationship between fashion and technology.

Recently, through the application of 3D cloth simulation and generative AI, the brand has proposed a new concept called “LIMINAL WEAR,” which perceives clothing as a space of boundary situations. Mr. Nagami is a promising designer who also won the "TOKYO FASHION AWARD 2025," the 10th edition of the award's series.

| *1 | Couture is the art of creating high quality custom-made clothing that is hand-tailored according to the needs of individual customers.

|

| *2 | ESMOD is a renowned fashion school in Paris, France, which is highly regarded especially for fashion design and fashion business. Founded in 1841, the school is known as a pioneer in fashion education and has produced many famous designers and stylists from around the world. |

Comment from Keisuke Nagami

We are always aware that the mass production of copies based on the original clothing in any form puts a considerable burden on the environment. But why do we continue to make clothes on a small scale? I'm always asking myself questions as I continue to create.

For example, in what I think should be a prototype for the "new normal", HATRA uses digital technologies such as 3D cross simulation and generative AI to continuously search for design methods that smoothly connects the entire production process. In the past, it was necessary to devise printing techniques and data formats according to the characteristics of the fibers, but with FOREARTH, we were surprised to find that the excellent texture was maintained even for fabrics such as triacetate and cupra, which were considered difficult until now. When I saw the processed samples, I felt that it was not only about making the process, but also about lightly expanding the possibilities of design, which have been narrowing unwittingly, such as "this pattern for this fabric."

For this collection, we tried to create complex color expressions that make you feel the glitter of transparent objects such as ice and glass. To create a visual "transparency," you need to create a subtle gradient. When I saw processed samples printed by FOREARTH, I realized the high reproducibility. And the best part is that it achieves a soft texture that was difficult to achieve with pigment ink. The texture of the fabric is not lost at all, and it is finished as if it was the original color.

This time, I got very good results with recycled polyester broadcloth*, but if it is possible next time, I would like to work on the application of more expressive materials. In the future, I hope to be able to build the future of clothing manufacturing, where textiles, patterns, printed designs, and even sewing are smoothly circulated.

In addition, unlike the conventional method, a large amount of water is not used, which means that it can be installed anywhere. This not only eliminates drainage problems, but also reduces transportation costs and promotes the updating of the garment manufacturing process itself. There are a myriad of new ways to add color, and with this alone, we can see the future.

This collaboration made me realize that great innovation is about inspiring creativity, not just imposing constraints for a purpose.

| * | A high-density plain fabric with horizontal ridges on its surface. |

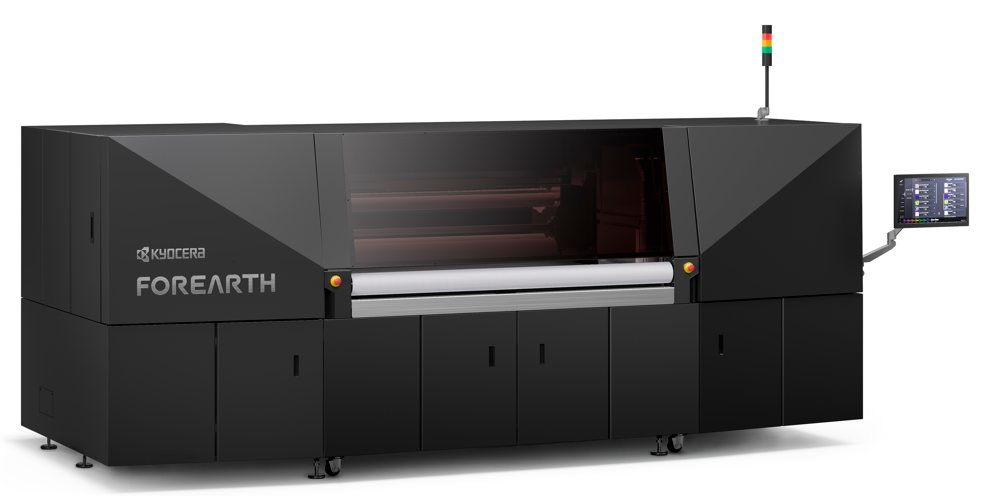

■Inkjet Textile Printer "FOREARTH" (More information can be found here.)

Through its FOREARTH sustainable inkjet textile printer, our company is continuously creating ways to contribute to the world of digital textile printing by solving various social issues facing the world with the power of technology and creating a better future.

Water pollution during textile printing has long been an issue in the apparel industry, and FOREARTH uses environmentally friendly materials and employs a printing technology that uses almost no water, thereby significantly reducing water consumption compared to conventional textile printing methods. We have also established a sustainable production process by reducing waste and improving energy efficiency. These efforts contribute to reducing the environmental impact of the fashion industry.

We will continue to pursue innovation and promote positive changes across the industry to achieve a sustainable society.

<List of outfits with fabric printed by FOREARTH>

Inquiries

Customers except within EU

KYOCERA Document Solutions Inc., Corporate Communication Section

Customers within EU

KYOCERA Document Solutions Europe B.V.

Kyocera Document Solutions Inc. ensures adherence to local data protection regulations. We have detected that your inquiry comes from within the EU. Therefore, due to the EU's General Data Protection Regulation, please note that your request will be forwarded to our regional headquarter: Kyocera Document Solutions Europe.

| * | This article is current, as of the date of publication. |