-

Hole Transport Material Contributing to the Development of Perovskite Solar Cells

Kyocera Document Solutions’ proprietary hole transport material (HTM) technology enhances development efficiency and ensures stable quality. We welcome inquiries regarding samples.

Toward a Sustainable Society

Perovskite solar cells, anticipated as a next-generation renewable energy technology, require the integration of diverse technologies for practical application.

Kyocera Document Solutions leverages its hole transport material (HTM) technology, developed through years of experience working on organic photoconductor (OPC) drums for office equipment like multifunctional devices and printers. This expertise plays a valuable role in improving the development efficiency of perovskite solar cells, whose early practical use is highly anticipated.

Furthermore, by applying the rigorous quality control know-how accumulated through mass production of OPC drums, we have established a reliable system for consistently supplying high-quality materials.

Our company has achieved both environmental impact reduction and cost efficiency in the office equipment field. Moving forward, we will support the increased adoption and technological advancement of perovskite solar cells from a materials perspective, helping to build a more sustainable society.

Kyocera Document Solutions leverages its hole transport material (HTM) technology, developed through years of experience working on organic photoconductor (OPC) drums for office equipment like multifunctional devices and printers. This expertise plays a valuable role in improving the development efficiency of perovskite solar cells, whose early practical use is highly anticipated.

Furthermore, by applying the rigorous quality control know-how accumulated through mass production of OPC drums, we have established a reliable system for consistently supplying high-quality materials.

Our company has achieved both environmental impact reduction and cost efficiency in the office equipment field. Moving forward, we will support the increased adoption and technological advancement of perovskite solar cells from a materials perspective, helping to build a more sustainable society.

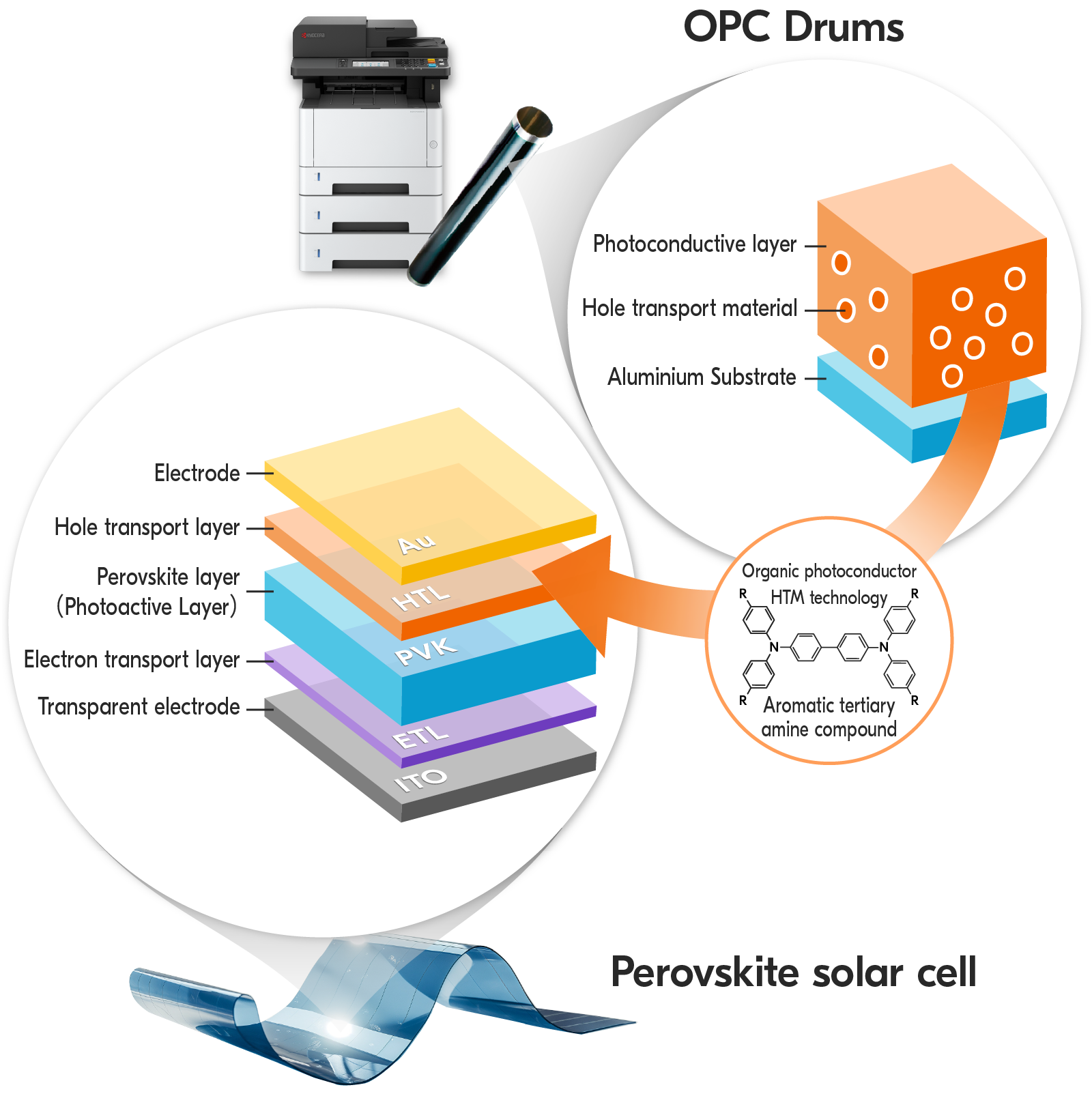

Commonalities Between Perovskite Solar Cells and OPC Drums

Both perovskite solar cells and the core components of multifunctional devices and printers, the OPC drums, are devices that convert light energy into electrical energy. Their structures and physical properties share many similarities.

-

OPC Drums for Multifunctional Devices and Printers

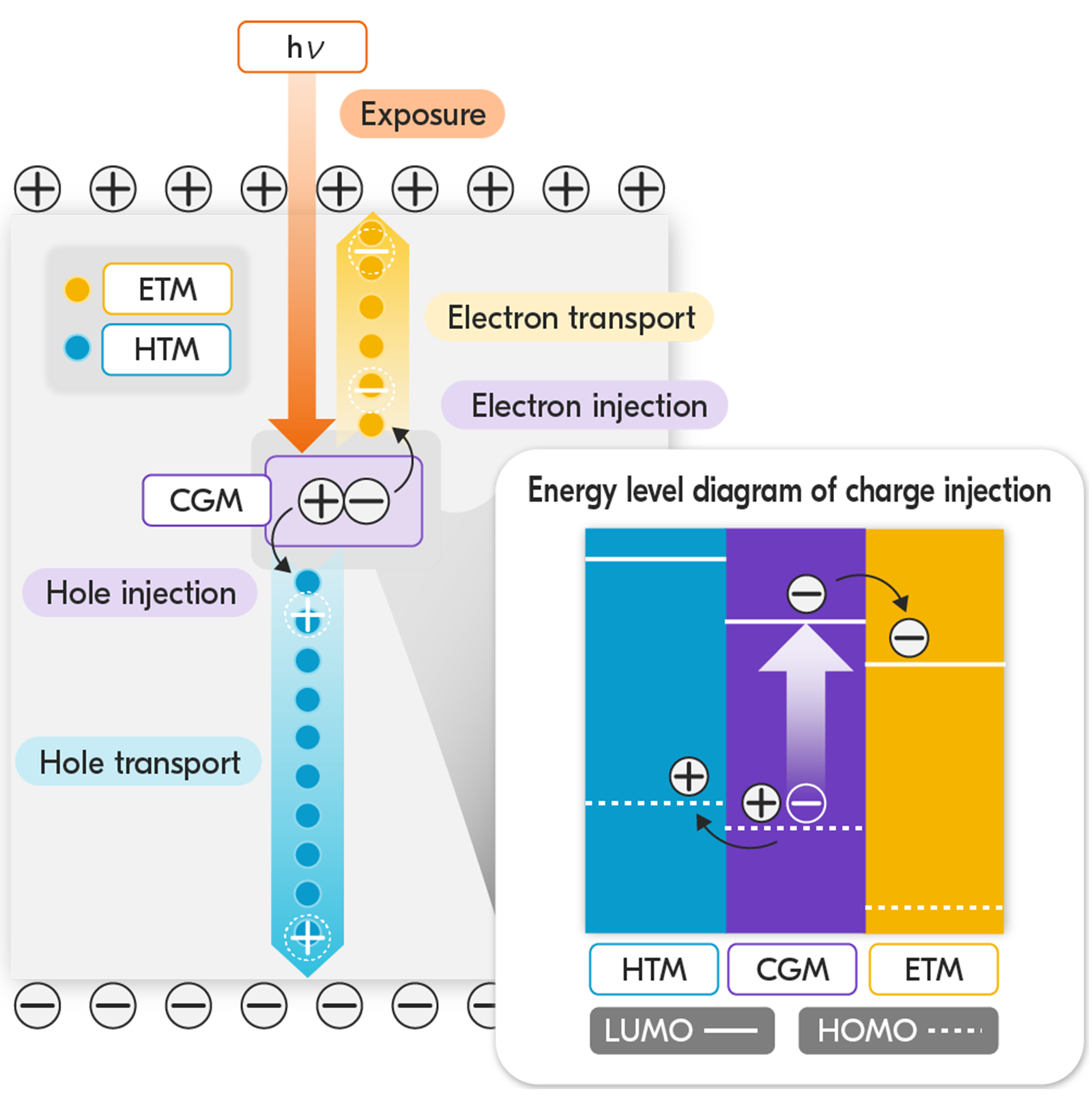

These devices generate charge (electrons and holes) upon light irradiation and transport them within the device to form an electrostatic latent image on the photoconductor surface. HTMs are used in the hole transport process, which is critical for image formation. -

Perovskite Solar Cells

Upon light irradiation, electrons and holes generated in the perovskite layer are efficiently separated and transported to the electrodes to generate electromotive force. HTMs transport holes to the positive electrode to extract current.

Our Strengths in HTM Technology for Perovskite Solar Cells and OPC Drums

-

Utilization of Organic Molecules and Polymers

Our molecular design technology and the excellent hole transport properties of organic small molecules and polymers, such as aromatic tertiary amine compound used in OPC drums, can be applied to the hole transport function in perovskite solar cells. -

Importance of Hole Mobility

In perovskite solar cells, holes generated by light must be efficiently collected at the positive electrode. By applying high hole mobility design echnologies developed for OPC drums to meet demands for high speed and long life, we reduce charge recombination and achieve high conversion efficiency.

-

HOMO Level Design

High conversion efficiency in perovskite solar cells requires proper alignment between the valence band of the perovskite layer and the highest occupied molecular orbital (HOMO) level of the HTM. For OPC drums, we optimize the HOMO level of HTMs to effectively utilize charges generated by light irradiation, an approach that can be effectively applied to perovskite solar cells as well. -

Stability and Durability

Long lifespan is a critical challenge for perovskite solar cells. Technologies developed for OPC drums to achieve high stability against light, heat, and oxygen (oxidation) can be applied. Additionally, we can optimize and propose multi-component formulations, including additives, with careful consideration of device structure design. -

Utilization of Evaluation Technologies

Beyond molecular design, we offer evidence-based proposals grounded in our proprietary evaluation technologies. -

High Quality Stability and Comprehensive Technical Support

By leveraging production and quality control technologies for high-purity HTMs used in OPC drums, we provide stable performance and quality. Our expert staff will support you even after product introduction, ensuring peace of mind.

Kyocera Document Solutions’ HTMs for Perovskite Solar Cells

We have finalized preparations for mass production of HTMs for perovskite solar cells and offer prototypes of consistent quality to meet customer needs.

We are also actively developing new HTMs with enhanced performance, and we offer contract development services customized to meet your specific goals.

We are also actively developing new HTMs with enhanced performance, and we offer contract development services customized to meet your specific goals.

Available Prototype HTMs:

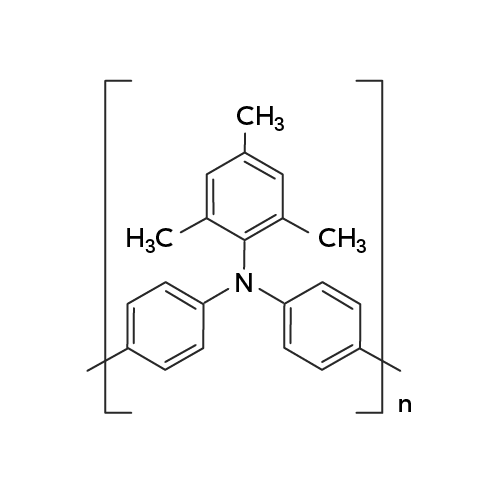

PTAA

Chemical formula: [C6H4N(C6H2(CH3)3)C6H4]nForm: Solid

Molecular weight: Average Mn 7,000–12,000 (GPC)

Hole mobility: P-type (μ = 0.52 × 10⁻⁴ cm²·V⁻¹·s⁻¹) *1

*1 Sustainable Energy Fuels, 2025, 9, 2689 (The Royal Society of Chemistry)

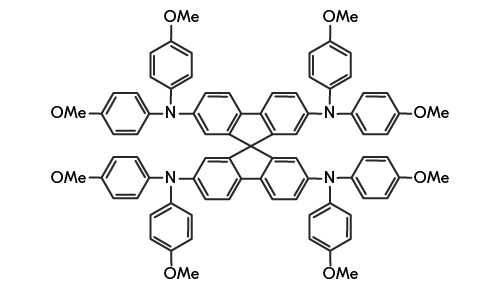

Spiro-OMeTAD

Chemical formula: C81H68N4O8Form: Solid

Molecular weight: 1225.43

Hole mobility: P-type (μ = 0.32 × 10⁻⁴ cm²·V⁻¹·s⁻¹) *2

*2 ACS Applied Energy Materials, 2024, 7, 5937

HTMs Under Development:

New PTAA-based compoundsNew Spiro-OMeTAD-based compounds

New compounds with novel molecular frameworks

Please feel free to contact us with any questions or proposals.