Sustainability

Product Development Stage - Environmentally Conscious Products

Energy-Saving Design

Most of the electricity used by our MFPs, printers and production inkjet printers when they are in operation comes from standby power, which is consumed constantly while a device is waiting for faxes or connecting to a LAN, and power consumed during the printing operation to melt toner or ink and fix it onto paper as an image. In order to minimize these types of power consumption, we are developing various new technologies and applying them to our products.

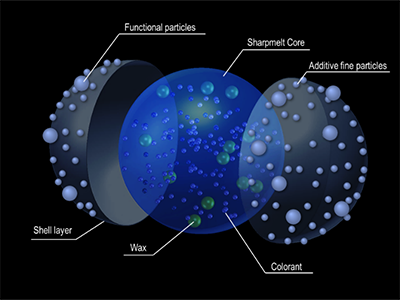

New Eco-friendly Toner

We developed a new toner featuring a sharp melting core covered by a thin shell. This new toner, which can fuse at a temperature 30℃ lower than that of conventional products, has halved the TEC value*1 of our MFPs and printers.

*1 The cumulative power consumption for one day (including 1.power during sleep, 2.power during printing, and 3.power during stand-by) when operating the MFP or printer for 4 hours in the morning (16 times of 15 minutes) and 4 hours in the afternoon (16 times of 15 minutes), and totaling it for one week (5 business days + weekend) will be measured in kWh/week.)

(* The time varies depending on the printing speed.)

New Energy-saving Ink

Our proprietary water-based pigment inks used in the TASKalfa Pro 15000c production inkjet printer demonstrate excellent penetration into paper and dry quickly after printing. These properties have enabled us to reduce the amount of electricity consumed when fixing images onto paper.

In addition, our proprietary developed ink has achieved VOC reduction during high-speed printing through material selection. In the field of commercial printing, such as offset printing and other analog methods, VOC emissions during printing operations are typically managed by installing exhaust ducts and recovery treatment systems to comply with industry and regional emission standards. The TASKalfa Pro 15000c, however, does not require such facility installations due to its low VOC emissions, thanks to the use of our proprietary developed ink. This printer, designed for commercial printing, contributes to reducing environmental impact.

New Energy-saving Controller

As demands grow to reduce power consumption and CO₂ emissions, cutting standby power for MFPs and printers in office environments has become a critical challenge. At the same time, these products must preserve user convenience and productivity, deliver prompt, reliable printing from standby without compromising the customer experience.

To meet these requirements, our company has developed an energy-saving controller that minimizes standby power consumption while enabling rapid wake-up from standby. MFPs and printers equipped with this energy-saving controller achieve industry-leading standby power consumption of 0.5 W or less, without impairing user convenience or productivity.

Resource-saving Design

Reusing Toner Containers

The TASKalfa 6052ci Series of A3 color MFPs released in July 2016 feature the capability of reusing the empty black toner container as a waste toner tank. Conventional models use a tank to collect waste toner, which needs to be replaced with another tank when it's full. Reusing a used toner container as a waste toner tank can reduce the number of parts needed and lead to resource and cost savings.

Reducing the Use of Sheet Metal

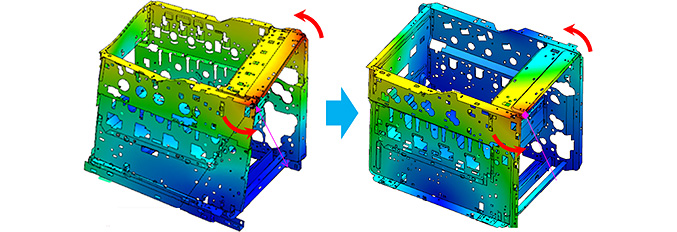

The frame of the A4 color MFP "ECOSYS M6535cidn" is composed of sheet metal parts.

We used CAE*2 tools to perform a structural analysis enabling us to find the optimal sheet metal configuration that would provide sufficient strength using thinner sheets and in the end came up with an MFP that is approximately 20% lighter than the previous model. The following two diagrams show an example of the resource-saving design obtained by changing the shape of sheet metal body based on a structural analysis via CAE. The arrows show the directions of torsion. The deeper the shade of red, the greater the stress applied to the sheet metal. Conversely, the deeper the shade of blue, the less stress there is. The diagram on the left shows greater stress being applied to the top right part. We used thicker metal for the red area and added another sheet to the left side of the frame to increase its strength while minimizing the thickness of the metal in other parts to reduce the amount of sheet metal used.

*2 Computer-Aided Engineering: Computer systems to support designing and developing industrial products.

Initiatives for reducing packaging materials

We are working on reducing packaging materials and improving transportation efficiency by making packaging cases more compact through innovations in the shape of cushioning materials. Additionally, we are promoting the use of pulp molds made from recycled paper to replace plastic cushioning materials.

Award-winning packaging cut model

Award-winning packaging cut model

Long-life Design

Our ECOSYS product concept focuses on extending the life of the mechanical parts, which are involved in creating the printed image, to the maximum extent possible. This will reduce the frequency of replacing parts and the number of parts that will end up as waste. Since running costs can also be minimized, there are both economic and environmental advantages. Our various unique technologies for extending service life are the driving forces that have made this dream a reality.

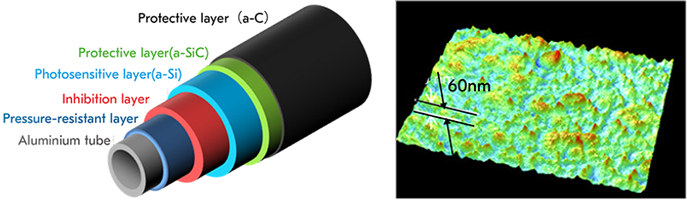

New Long-life a-Si Photoreceptor Drum

The a-Si (amorphous silicon) photosensitive drum, which forms the core of the ECOSYS Concept, was first introduced in the first-generation ECOSYS printer, the "ECOSYS FS-1500," in 1992. It boasted industry-leading longevity of 300,000 pages as a device.

In 2011, a-C (amorphous carbon) thin film, which has a hardness close to that of diamond and superior durability, was adopted as the surface protection layer for the conventional a-Si photosensitive drum. This extended the lifespan of the photosensitive drum to over 1 million pages, ensuring exceptional durability.Furthermore, since 2016, a sub-micron-sized (1/10,000 millimeters) fine irregular shape has been formed on the outermost layer of the drum surface. This reduces friction with the cleaning blade by approximately 30%, prolonging the lifespan of peripheral devices. As a result, the photosensitive unit achieves an industry-leading lifespan of 600,000 pages (φ30mm photosensitive drum).

Moreover, by reducing friction, the power consumption during photosensitive drum operation is reduced by 30%, making a significant contribution to reducing CO₂ emissions.

The a-Si photosensitive drum has fast photosensitivity, enabling it to be integrated into high-speed engines. Additionally, the electrostatic latent image formed by laser light is sharp, allowing for high-resolution image formation.

Long-life a-Si photoreceptor drum

Long-life a-Si photoreceptor drum

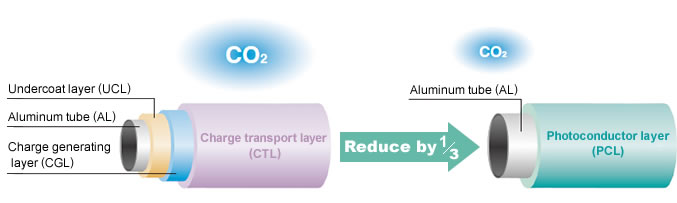

New Long-life PSLP*3 Drum

A number of photoreceptor drums employed in our MFPs and printers on the market today feature a positive-charged single-layer photoconductor (PSLP) drum that can be used with a positive charge unlike standard organic photoconductors (OPCs). While the conventional negatively charged multi-layered OPC drum causes deterioration in the special photoreceptor balance due to wear and tear on the surface layer of this multi-layered component, the PSLP drum's single layer structure provides sustained stability over a long period without any deterioration in the special photoreceptor balance despite the wear and tear. Incorporating our own original service life extension technology into this design, we were able to create a drum that lasts ten times longer than the standard OPC drum. Since the manufacturing process for PSLP drums is extremely simple compared to that for standard OPC drums, it takes about 1/3 the amount of energy to manufacture them as it does to manufacture standard OPC drums of the same size and contributes significantly to a reduction in CO₂ emissions.

※3 Positive-charged Single Layer Photoconductor

Long-life Printhead

Inkjet printers effectively remove ink and dirt that dry on the print head surface to keep it clean at all times. We developed an original cleaning solution that dissolves the dried ink for the TASKalfa Pro 15000c production inkjet printer. The cleaning solution is fed from a special nozzle installed at the end of the head to the wiper blade that cleans dirt off the head's surface. Also featuring a built-in cleaning system that gives a final wipe using only the cleaning solution and then cleans the wiper blade, it can print up to 60 million pages without maintenance. This cleaning system reduces the amount of maintenance required, which means a smaller environmental impact since it generates less waste fluid and saves water resources associated with maintenance.

Image of print head cleaning

Image of print head cleaning

Office Friendly Products

In addition to making our products environmentally friendly with resource and energy saving designs, we are taking on the vital task of improving our customers' office environments as well. Our MFPs and printers are equipped with the exact features required in today's workplace environment, such as a small footprint, quiet operation that does not disturb people working near the machine, a quiet mode setting which is useful when a quiet office environment is especially necessary, and a compact design.

Quiet By Design

We have incorporated various features in our MFPs and printers that are designed to make them quiet.

Reduction of Cooling Fans

The A4 color MFP "ECOSYS M5526cdw" reduced the number of cooling fans by rearranging their placement so that the impact of heat sources can be minimized, and fan noise reduced.

● Flow of Air in the ECOSYS M5526cdw

Reduction of Driving Motors

The A4 color MFP "ECOSYS M5526cdw" dramatically reduced the torque of the process and paper feeding units to successfully run the machine with only two motors, one motor for the image forming and the other motor for the feeding, which has significantly cut down operational noise.

| Model | Previous model | New model | Reduction |

|---|---|---|---|

| Color A4 MFP ECOSYS FS-C2626MFP | Color A4 MFP ECOSYS M5526cdw | ||

| Sound Pressure Level | 50.0 dB | 49.0 dB | x0.89 |

| Sound Power Level | 61.7 dB | 60.1 dB | x0.69 |

Quiet Mode

The following five models of A4 color MFPs and printers can be operated very quietly by reducing the noise. The user may choose to always leave it on quiet mode, turn off quiet mode entirely, or set it to quiet mode for particular jobs. Quiet mode enables users to lower the noise level to 45 - 47 decibels.

* 40 dB is equivalent to the noise level of typical city street at midnight or inside a library, while 50 dB is about the same as a quiet office.

| Model | Noise level | |

|---|---|---|

| Normal mode | Quiet Mode | |

| ECOSYS M6530cdn/P6130cdn | 49.5 dB | 45.0 dB |

| ECOSYS M6535cidn/P6035cdn | 52.0 dB | 47.0 dB |

| ECOSYS P7040cdn | 53.5 dB | 47.0 dB |

Compact Design

The color A4 MFP "ECOSYS MA3500cifx" and the color A4 printer "ECOSYS PA3500cx," which were launched for sale in September 2023, achieved a compact design of the main unit by adopting the following features:

- Reduction in scanner height by incorporating a CIS module into the original table reading unit.

- Shortening of the optical path length by employing a short focal length ƒθ lens in the LSU (Laser Scanner Unit), which is used for writing images onto the drum in laser printers.

- Shortening of the secondary transfer to fixing distance by achieving highly precise control of the conveyance speed, preventing image defects caused by paper pulling between these processes.

- Achieving compactness by enhancing the cooling efficiency of the discharge unit to mitigate the toner adhesion to the conveyance guides, which occurs due to the high pressure exerted on the paper by the conveyance guides when the discharge unit's height is minimized.

These improvements enhance panel visibility when the devices are placed on a desktop and improve the handling of scanned documents on the original table and document feeder.

| Unaddressed model | Addressed model | Effect | |

|---|---|---|---|

| Color A4 MFP ECOSYS M6635cidn | Color A4 MFP ECOSYS MA3500cifx | ||

| Total Height [mm] | 620 | 575 | 7.2% reduction |

| Volume [L] | 171.71 | 159.39 | 7.1% reduction |

Ozone-free

Our products use photoreceptor units that can be used with a positive charge and curb the generation of ozone, such as an amorphous silicon (a-Si) drum and a PSLP*3 drum. In overhauling the old charging system, we've combined a positively charged photoreceptor drum and a roller charging system to reduce the amount of ozone generated by the machine to an almost undetectable level. We have been using this ozone-free design since 2010.

● Ozone-free design