Home > Sustainability > Feature in FY2014 > Reformes to improve quality Part.1

Feature in FY2014:

Reformes to improve quality Part.1

Reformes to improve qualityQuality control measures that overturn conventional ideas result in more professional products and services

Based on the belief that high quality benefits society financially and in terms of happiness, KYOCERA Document Solutions has started preparing concepts and measures in an effort to create new value by improving quality. This feature highlights some of our reforms.

Quality control measures that overturn conventional ideas result in more professional products and services

Since April 2013, the KYOCERA Document Solutions Group has been engaged in reforms to improve quality. These innovative reforms have been accomplished by reexamining the basics of quality control to take a fresh look at the reliability of products that enter the marketplace and the quality of after-sales services. This will fundamentally change our approach to how we perform our work, and establish new process steps and decision-making criteria.

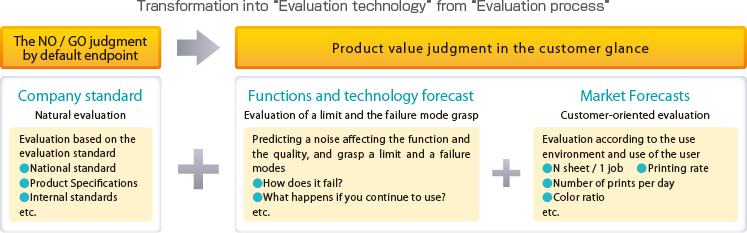

Evaluation technology over evaluation process

The ultimate goal of the reforms is to supply professional products and services. Previously, the primary function of quality assurance departments was to confirm that products functioned accurately when used by the customer so that they achieved their intended purpose. Products were evaluated from the perspective of passing them if no problems were discovered during tests. However, with ongoing globalization and the emergence of new IT technologies, that approach is no longer appropriate for today's world. Therefore, we need to closely examine whether or not products are beneficial to customers or cause any problems assuming in advance that customers will be using the products in various environments in a wide variety of ways.

Consequently, we are now expecting quality assurance personnel to go from the conventional "evaluation process" mentality to an "evaluation technology" level where they can confirm target settings, have a correct understanding of the technology, and also adopt a broad quality engineering approach that is deeply contemplative and imaginative.

Specifically, this means understanding information and then describing and executing an evaluation plan. Therefore, to better utilize historical data, such as information from troubleshooting databases, and broaden our knowledge and perspective, we have been discussing a wide variety of topics on a daily basis and conducting various training sessions on topics outside our normal areas of expertise.

Linking engineering, manufacturing, and service in an organic manner

In terms of evaluating product reliability and guaranteeing new products, we are introducing a system for ensuring reliability that involves reliability engineering methods and other new techniques to evaluate durability and understand the limits of how the materials affect the function of products. Only then can we be confident that our products will be reliable under highly diverse market applications. In addition, we are implementing measures to raise the technical understanding level of manufacturing personnel and improve product quality down to each component part by creating quality control techniques intended for factory manufacturing processes. Meanwhile, we are upgrading and using statistical methods to process our service information, which is accumulated to serve as a resource for building the next manufacturing process. We predict this will generate new signs of growth due to synergistic effects from technical information.

This is because the quality assurance departments will also have the important role of organically linking the three functional areas of engineering and R&D, manufacturing, and market support, based on the keyword "quality."

Home > Sustainability > Feature in FY2014 > Reformes to improve quality Part.1