Home > Sustainability > Feature in FY2009 > CSR activities at Kyocera Mita's Shilong Plant

Feature in FY2009:

CSR activities at Kyocera Mita's Shilong Plant

- Aiming at MONOZUKURI trusted throughout the world.

- Through integrated collaboration between suppliers and employees.

Through integrated collaboration between suppliers and employees.

to check the RoHS Directive

target chemicals

Controlling chemical substances is one of the most important issues for the Shilong Plant in terms of upholding the "Quality First" policy. We conduct audits on suppliers to ensure Green Procurement.

Designating parts suppliers

In compliance with the EU RoHS Directive that took effect in 2006, we conclude with each parts supplier a comprehensive agreement inhibiting the use of all target chemicals under the Directive, and also check the chemical substances used in each part using the "Chemicals Check Sheet." We only deal with suppliers that have been designated after having passed documentary screening by the Head Office (in Japan).

Moreover, we conduct various environmental audits to check the status of chemicals control and acquisition of ISO14001 certification, process control & shipment control systems, the work environment, and so on.

Implementation of parts acceptance inspection

Upon receiving parts, we conduct random inspection for size and for the RoHS Directive target chemicals, and sampling inspection after design change or for new products.

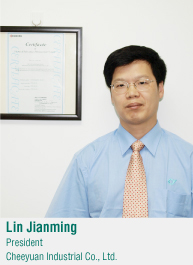

Designating parts suppliers

We are celebrating the 24th year of our relationship with Kyocera Mita, which started in 1984. Over these years, Kyocera Mita has unwaveringly maintained strict quality control and, since the RoHS Directive took effect, we have had to pass the supplier audit conducted every two years. We make every effort to satisfy their requirements; we ask our upstream suppliers to report in a sheet the content of each chemical substance used, while having our strict acceptance inspection and process control certified by third party organs. The audit for fiscal 2008 was held in June, which we passed once again.

The great thing about Kyocera Mita is that it places more emphasis on written communication than on verbal communication at conferences or by telephone. This reduces misunderstandings and losses, enabling speedy and proper handling of matters. The fact that we've had no troubles associated with misunderstandings in communication over the past ten years is the best evidence of our success. I hope Kyocera Mita will further enhance its global operations and promote its Ecosys concept widely. I wish our relationship will continue for further long years. Through this relationship, we hope to contribute greatly to society, and to the world.

instrument in shipment inspection

RoHS-designated

substances

Company profile

- Head Office

- Hong Kong

- Established

- 1969 (founded in 1965)

- Number of employees

- 2,397

- Businesses

- Resin molding, metal molding, plastics, plating, emergency power batteries, etc.

ISO14001 acquisition: October 2001

Designated as a Kyocera Mita supplier: June 2006

We supply resin molded parts for MFPs and printers to Kyocera Mita.

Environmental measures that change the minds of employees

In accordance with the ISO14001 management system, the Shilong Plant implements various environmental measures by setting up several action plans for energy saving, waste disposal, waste water treatment, etc., following the Plan-Do-Check-Act (PDCA) cycle.

Energy saving

contributed greatly to

energy saving

To reduce power consumption, the Shilong Plant pays careful attention to the use of electricity. For air-conditioning systems, such actions as the replacement of freezers with the turbo freezers with higher energy efficiency; the installation of timers to coolers so that they can be turned on and off automatically, and the "Keep the room temperature at 26A℃" campaign are promoted. Regarding lighting, rigid control of the illuminance level, reduction of the number of lights in use, switching to energy-saving types, etc., are encouraged. As a result of these measures, electricity consumption in June and July in 2008 both marked a 10% decrease from the same months of the previous year.

Waste disposal

collection

All waste items are sorted into three categories: "recyclable," "non-recyclable," and "hazardous," to be disposed of separately. Resin, metal and corrugated cardboard items are sold as valuable resources, while daily garbage and toners are carried over to our contract disposers. Each office has three garbage boxes in its staff kitchen, encouraging the separate collection of metal, plastic and regular waste.

Wastewater treatment

Water quality is measured periodically at two wastewater treatment facilities located inside the Plant, and also by external institutions. Having constantly satisfied the wastewater standards of its local Dongguan City and passed all the surprise tests by the government, the Shilong Plant has received an award from the City and been granted preferential treatment concerning water rates.

Effective use of resources in logistics

transportation of

products shipped to

Japan

for delivery from/to

suppliers

Packaging material for the transportation of parts between the Plant and suppliers was changed from corrugated cardboard to plastic. For shipment to Japan, metal pallets have been used instead of wooden pallets since 2005. The Shilong Plant contributes to the effective utilization of resources by promoting use of these returnable materials.

Products manufactured and sold by the Shilong Plant have acquired the Chinese Green Mark (13 models) and the Energy Conservation Mark (16 models).

Previous pageAiming at MONOZUKURI trusted throughout the world.

Home > Sustainability > Feature in FY2009 > CSR activities at Kyocera Mita's Shilong Plant

I am proud of working for environmental conservation, as it contributes to both my company and society.

Although various environmental policies have been introduced in China these days, it is still not easy to make Chinese employees understand the importance of daily, steady actions for energy saving such as the sorting of waste. We call for a meeting of the representatives in charge of environmental affairs from all departments every month, and to have them explain the results of the discussions to the members of their own departments. We also take various other measures to promote employees' understanding, such as putting information on bulletin boards and having environmental issues included in the basic freshman training course.

I am proud to work in environmental matters, as this contributes not only to the company but also to the wider society. I will make efforts to disseminate environmental awareness widely outside the Company, by teaching what I know about environmental conservation to my friends and family members.